下载

REV. 0

a

AN-564

APPLICATION NOTE

One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106 • Tel: 781/329-4700 • Fax: 781/326-8703 • www.analog.com

© Analog Devices, Inc., 2001

A Power Meter Reference Design Based on the ADE7756

By Stephen English and Dave Smith

INTRODUCTION

This application note describes a high-accuracy, low-cost

power meter based on the ADE7756. The design is for use

in the North American 3-wire/single-phase application.

This meter may also be used in a single-phase, 2-wire dis-

tribution system with a minimal amount of changes. The

reference design is comprised of the ADE7756, a micro-

controller, LCD display, serial interface, and power supply.

The ADE7756 is designed to interface to a microcontroller

through a serial interface (SPI). The SPI port allows the

user to calibrate various components of the meter,

including gain, offset, and phase errors. The purpose

of the microcontroller is to send display data to the LCD

and control the various functions of the meter. An

EEPROM is used to store various calibration param-

eters of the meter and store the meter’s data during a

power-down. The entire meter is calibrated through

an external calibration routine by a PC through an

external SPI interface.

The ADE7756 is comprised of two ADCs, a reference cir-

cuit, and all the signal processing necessary for the

calculation of real (active) power. Circuitry is provided to

null out various system errors including gain, phase,

and offset errors. Additional circuitry provides wave-

form sampling, programmable interrupts, and power

line monitoring. All registers of the ADE7756 are avail-

able through the SPI port. (See the ADE7756 data sheet

for their descriptions.) The data sheet provides detailed

information on the functionality of the ADE7756 and will

be referenced several times in this application note. This

application note should be used in conjunction with the

ADE7756 data sheet.

Design Goals

The goal for this meter is to comply with the ANSI C12.16

specifications. The reference design is for a single ele-

ment, Class 100 meter in a form 2S designation. This

designation complies with the wiring arrangements as

defined in ANSI C12.16-1991. Although the design in this

application is limited to the ANSI standard, the accuracies

achieved are well within the accuracy requirements of the

IEC1036 standards for a Class 1 meter. For reference, see

the section at the end of this application note, comparing

the IEC1036 and ANSI C12.16 standards. This section

explains the key IEC1036 specifications in terms of their

ANSI equivalents.

This design greatly exceeds the definition for many of

the accuracy requirements, e.g., accuracy at unity power

factor and at low (PF = ±0.5) power factor. In addition,

the dynamic range performance of the meter has been

extended to 500. The ANSI standard defines the maxi-

mum current of a Class 100 watt-hour meter as

100 amps with a reference current (I

REF

) of 15 amps. The

Accuracy Class is defined in Table I for both the Accu-

racy Class 0.5 and Class 0.2 static watt-hour meters. The

current range (dynamic range) for accuracy is specified

in terms of I

REF

.

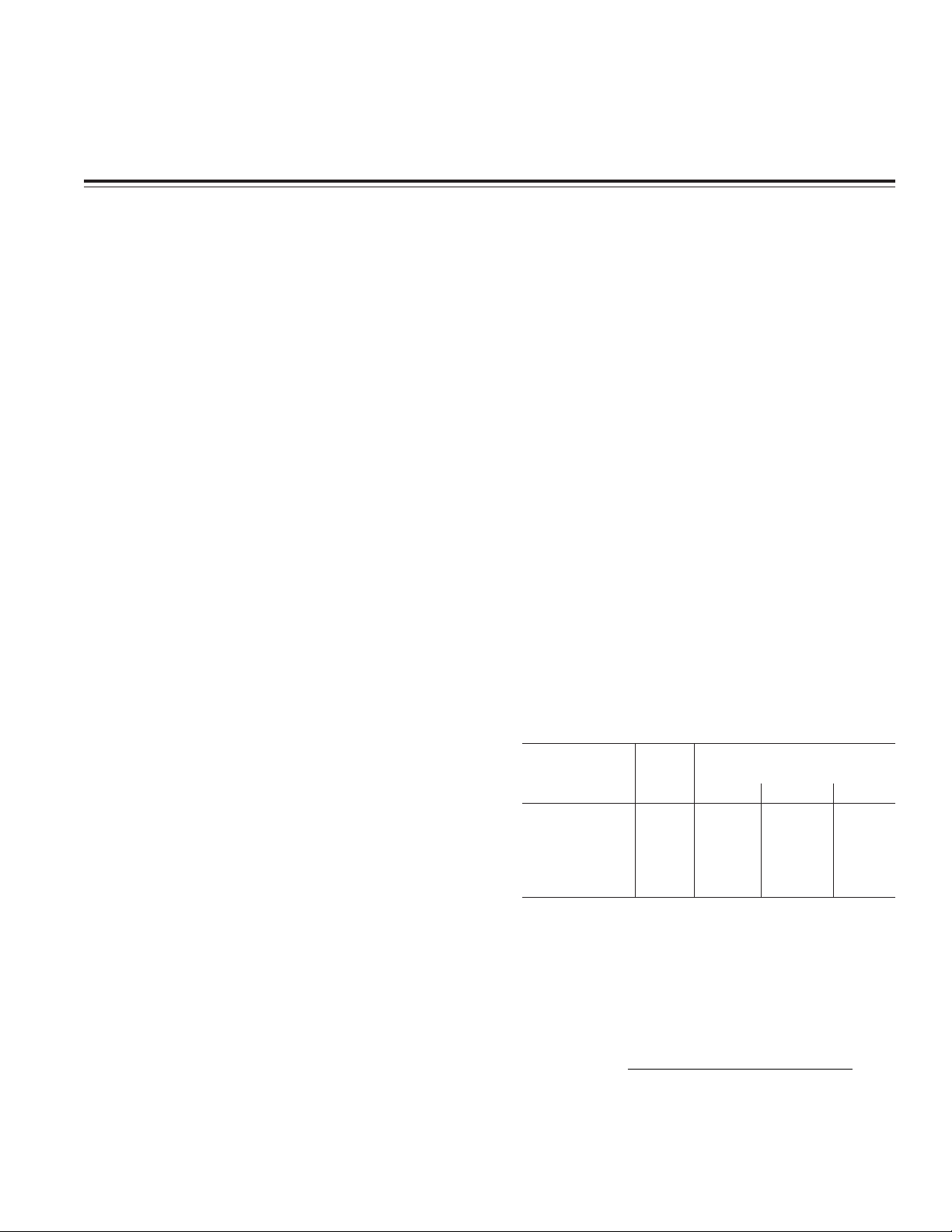

Table I. Accuracy Requirements

Percentage Error Limits

3

Accuracy

Current Value

1

PF

2

Class 1 Class 0.5 Class 0.2

0.1 I

REF

≤ I < I

MAX

1 ±1.0% ±0.5% ±0.2%

1 Amp 1 ±2.0% ±1.0% ±0.4%

3 Amps 0.5 lag ±2.0% ±1.0% ±0.5%

50 Amps 0.5 lag ±2.0% ±0.6% ±0.3%

100 Amps 0.5 lag ±2.0% ±0.6% ±0.3%

NOTES

1

The current ranges for specified accuracy shown in Table I are

expressed in accordance with Load Performance Test, ANSI C12.20-

1998 Section 5.4.2.3, Table IV, in terms of the reference current.

2

Power Factor (PF) in Table I relates the phase relationship between the

fundamental (45 Hz to 65 Hz) voltage and current waveforms. PF in this

case can be simply defined as

PF = cos(f)

, where

f

is the phase angle

between pure sinusoidal current and voltage.

3

Accuracy Class is defined as the limits of the permissible percentage

error. The percentage error is defined as:

Percentage Error =

Energy Registered by Meter — True Energy

True Energy

100%×