下载

MLX Trim&Form guide SIP Hall sensors short form -- Rev 3.1 osa / 15-03-2008, p 1/4

Application of SIP Hall Sensors

Lead trimming and forming recommendations

Lead trim & form operations are often applied on SIP packaged Hall sensor ICs during system

assembly, in order to position the sensor exactly at operating position and shape the leads to secure

electrical contacts by soldering on PCB or welding.

Significant forces are applied during trim and form operations. Without appropriate precautions

applied force may act as a stress factor to the plastic body of the sensor or to the leads relative to the

plastic body. Such stress may cause a device malfunction, kay parameter drift or introduce a

reliability risk (latent defect), like below:

- Stress applied on the branded side of the package may cause Hall element parameter drift or

silicone structure damage.

- Stress applied on the leads relative to plastic body may cause wire bond damage, package

crack or delamination from a leadframe. Cracks and delamination, if not leading to an

immediate malfunction, will further weaken wire bonds, allow moisture penetration and

bond corrosion – all reliability risks.

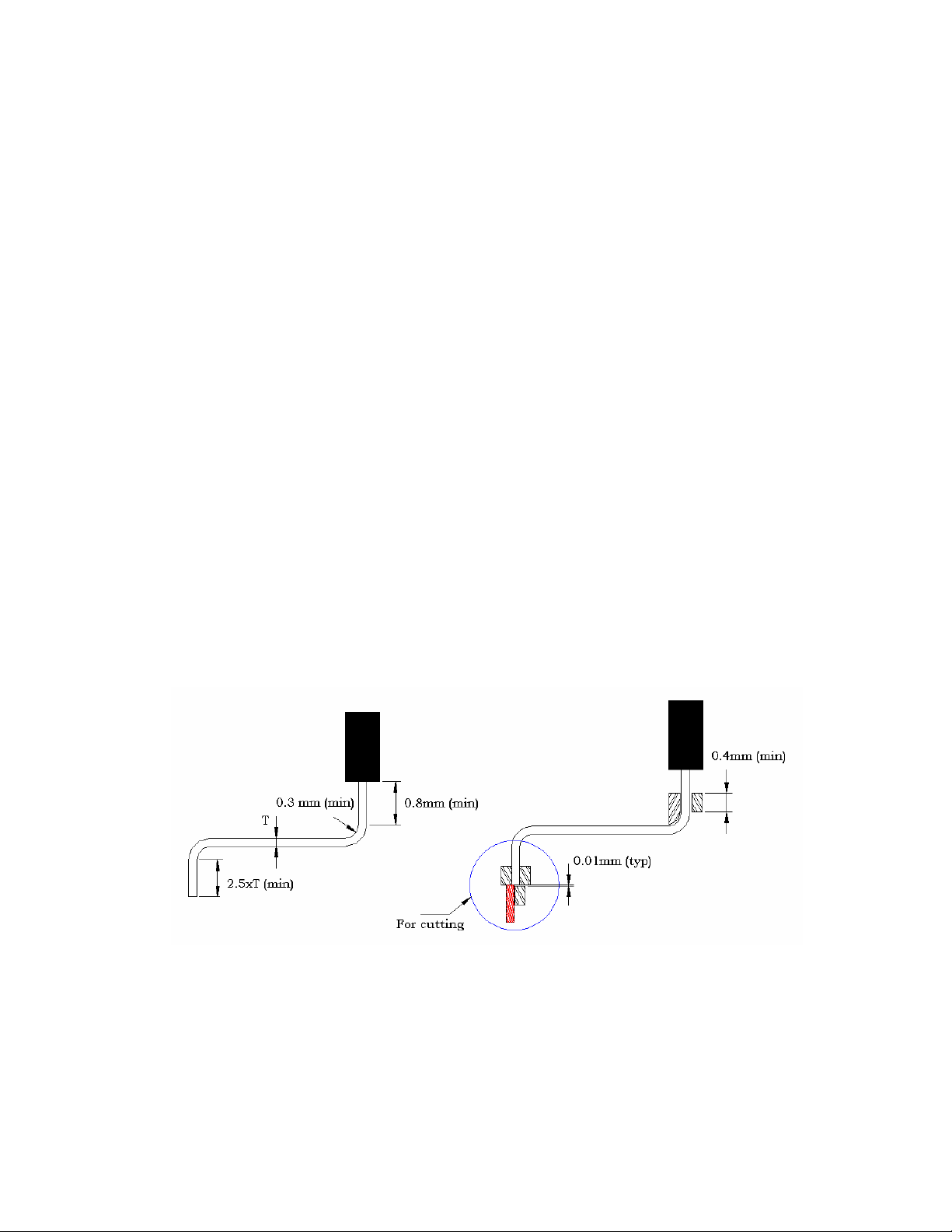

Lead clamping

Package stress relief shall be secured through steady clamping of leads from both sides

during trim or form operation (in the same direction as the trim or form action).

The stress relief clamp has to have a minimum pressing surface width of 0.4mm (1mm is

preferable) on both sides of the component pins, clamp lin shall be between the

bending(cutting) line and the plastic body.

Care has to be taken that the clamping force is strong enough to hold the component pins

i

n

p

l

a

c

e

b

u

t

w

ithout damaging the leads on the clamping position (locally flattening the pins). When

pneumatic cylinders are used to operate clamping and cutting/bending, the force of

clamping cylinder shall be minimum 3 times the force of the cutting/bending one.