下载

2004 Microchip Technology Inc. DS00937A-page 1

AN937

INTRODUCTION

Continuous processes have been controlled by

feedback loops since the late 1700’s. In 1788, James

Watt used a flyball governor on his steam engine to

regulate its speed. The Taylor Instrument Company

implemented the first fully functional Proportional,

Integral and Derivative (PID) controller in 1940.

Although feedback control has come a long way since

James Watt, the basic approach and system elements

have not changed. There are several elements within a

feedback system; for discussion purposes, we will use

a home heating temperature control system as our

model in the descriptions below.

• Plant – The physical heating and cooling parts of

the system.

• Sensors – The devices (thermistors measuring

temperature) that measure the variables within

the Plant.

• Setpoint – This is a value (i.e., 70 degrees),

which is converted to a voltage that the process

drives towards.

• Error Signal – This is the difference between the

response of the Plant and the desired response

(Setpoint). In a house, the thermostat may be set

to 70 degrees, but the temperature is actually

65 degrees, therefore resulting in an error of

5 degrees (Error = Setpoint – Measured).

• Disturbances – These are unwanted inputs to

the Plant, which can be common. A disturbance

would be an open entry door allowing a gust

of cold air to blow in, quickly dropping the

temperature and causing the heat to come on.

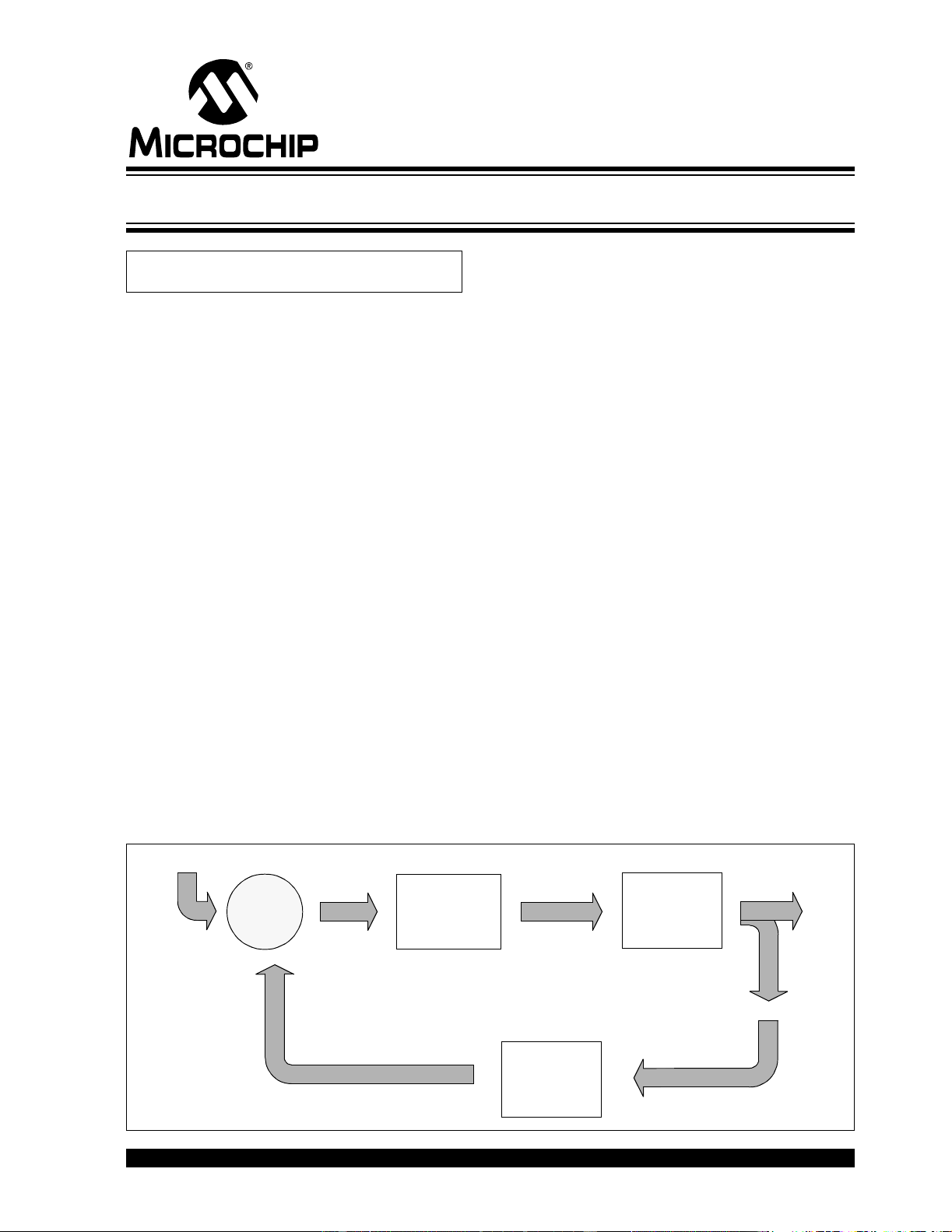

• Controller – Intentionally left for last, this is the

most significant element of a control system. The

Controller is responsible for several tasks and is

the link that connects together all of the physical

and nonphysical elements. It measures the output

signal of the Plant’s Sensors, processes the

signal and then derives an error based on the

signal measurement and the Setpoint. Once the

sensor data has been collected and processed,

the result must be used to find PID values, which

then must be sent out to the Plant for error

correction. The rate at which all of this happens is

dependent upon the Controller’s processing

power. This may or may not be an issue

depending on the response characteristic of the

Plant. A temperature control system is much more

forgiving on a Controller’s processing capabilities

than a motor control system. Figure 1 shows a

basic block diagram of a feedback control system.

FIGURE 1: FEEDBACK CONTROL LOOP

Author: Chris Valenti

Microchip Technology Inc.

Controller

Plant

Feedback

Setpoint

Error

Controller

Output

Process

Variable

–

+

Implementing a PID Controller Using a PIC18 MCU