下载

© Semiconductor Components Industries, LLC, 2012

December, 2016 − Rev. 3

1 Publication Order Number:

AND9031/D

AND9031/D

Constant Current Regulator

Charging Circuit

Abstract

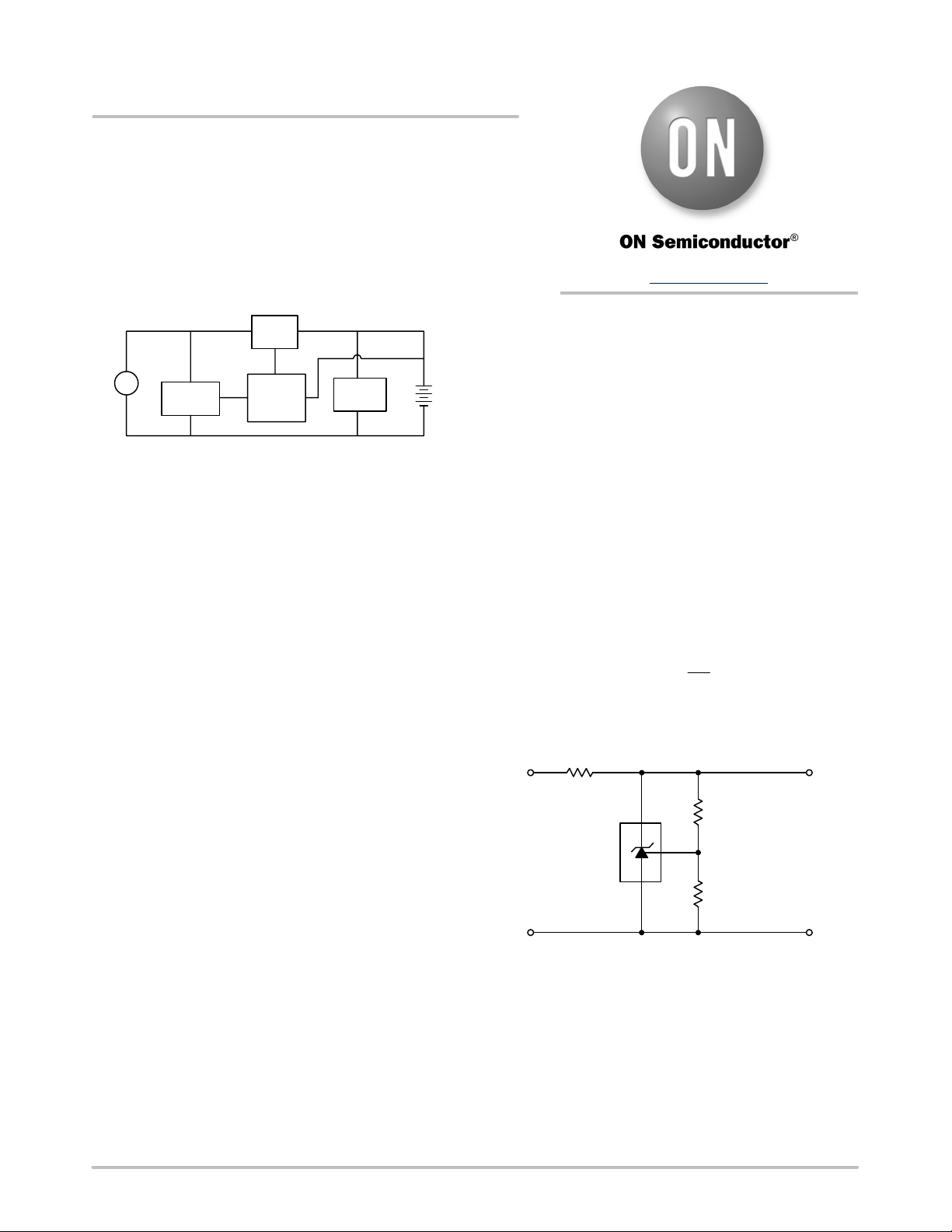

This application note describes how a Constant Current

Regulator, CCR, can be used in a low cost charging circuit

for rechargeable batteries, providing a simple controller to

terminate charging.

Figure 1. Block Diagram of Charging Circuit

+

−

Source

Current

Control

Voltage

Reference

Charge

Indicator

Controller

Battery

Types of Rechargeable Batteries

The three most common rechargeable batteries are Nickel

Metal Hydride (NiMH), Nickel Cadmium (NiCad), and

Lithium Ion (Li-Ion). When referring to the rate at which

a battery is charged the letter “C” is used. The “C” defines

the capacity of the battery over 1.0 hour. For example,

a battery rated at 800 mAh could be charged at 0.5C

resulting in a charge current of 400 mA over two hours to

fully charge the battery.

Nickel Metal Hydride and Nickel Cadmium

The nominal voltage of a NiMH battery is 1.2 V/cell and

should be charged up to 1.5−1.6 V/cell. There are several

different techniques for determining when to shutoff the

charge. They include: peak voltage detection, negative delta

voltage, delta temperature (dT/dt), temperature threshold,

and timers. For high end chargers these may be all combined

into one charger.

The CCR charger is a peak voltage detect circuit and

terminates charging at a predetermined peak. The

predetermined peak voltage is 1.5 V/cell, and will charge the

battery to ≈ 97%.

Nickel Cadmium batteries can be charged using this

circuit. They perform very similar to NiMH batteries so this

method will work well for them.

Lithium Ion

The usual method of charging a Li-Ion battery is to charge

the battery to 4.2 V/cell at 0.5C to 1C followed by a trickle

charge. The temperature rise of Li−Ion batteries should be

kept below 5°C while charging, a higher temperature rise

indicates a potential to combust. The trickle charge portion

of the charge cycle is when the battery temperature rises the

most and it has the greatest chance to combust. High end

charges use smart IC’s, such as the NCP1835B, to monitor

and control the charge of Lithium ion batteries because of

this issue.

The CCR controller discussed here eliminates this by not

including a trickle charge, keeping the battery in a safe

operating area and helping to increase the life of the battery.

However, by eliminating the trickle charge the battery will

only receive ≈ 85% charge.

Setting the Reference Voltage

The TL431, a three-terminal programmable shunt

regulator, is used to set the reference voltage. It is designed

to give a constant 2.5 V output at its reference pin. When two

external resistors are connected as shown in Figure 2, the

reference voltage can be selected from 2.5 V to 36 V. For our

purposes we will set R

2

to 1.0 kW, and will adjust Rref to

match the reference voltage we want. The equation used to

find the ratio of R

2

/R

ref

is given by:

V

ref

+

ǒ

1 )

R

2

R

ref

Ǔ

2.5

The resistor that is connected to the cathode of the TL431

is used to limit the current, and to separate the input voltage

from the reference voltage.

Figure 2. Setup of Reference Voltage

V

ref

R

ref

R

2

R

1

V

+

Comparator with Hysteresis Loop

The LM311, a Single comparator, is used to compare the

voltage of the battery to the reference voltage. Connected to

the inverting input is the battery voltage. Hysteresis is

provided by a feedback resistor (R

h

) between the output and

the non-inverting input. R

3

, a 1.0 kW resistor is used to make

the ratio of R

3

/R

h

simple. By adjusting R

h

you can change

the bandwidth of the hysteresis loop. By increasing R

h

you

APPLICATION NOTE

www.onsemi.com