下载

© Semiconductor Components Industries, LLC, 2015

May, 2015 - Rev. 0

1 Publication Order Number:

AND9208/D

AND9208/D

Standby Power Performance

of NCP1256

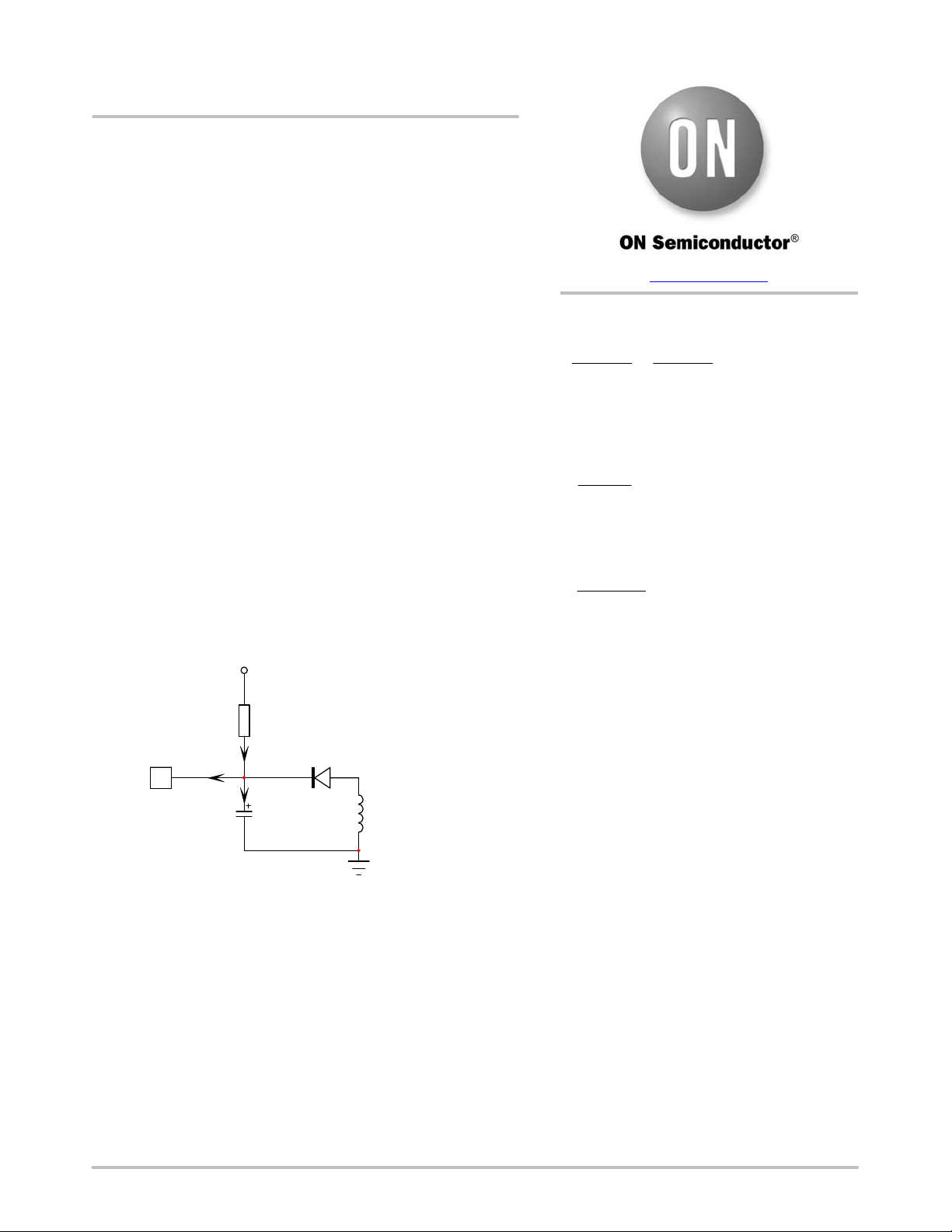

The NCP1256 has been optimized to improve converter

efficiency in light−load conditions but also in no−load

situations. By reducing internal bias currents as output

power goes down, the part consumption decreases

significantly, allowing extremely low standby power

consumption figures despite the absence of high−voltage

start−up current source. When brown−out sensing takes

advantage of the X2 discharge resistors, the part gives

excellent results as we will see.

Sources of Power Waste – Primary Side

A low−voltage die such as in NCP1256 needs energy to

start−up and crank the power supply. This energy usually

comes from the input mains and is stored into the V

cc

capacitor for starting up. Several tens of milliseconds after

the capacitor voltage hits the controller turn−on voltage, an

auxiliary winding takes over and self−supplies the

controller. A typical solution is shown in Figure 1 where

resistor R

1

forces a current I

1

from the high−voltage rail to

charge capacitor CV

cc

.

Figure 1. The Simplest Implementation to Start up

the NCP1256 from the Bulk Voltage

.

aux.

1

R

cc

CV

1CC

I

1

D

V

cc

V

bulk

1

I

2

I

5

The resistor current splits in I

2

for the capacitor but also

in I

CC1

, absorbed by the die until the V

cc

turn−on voltage is

reached. This I

CC1

current has been reduced compared to the

existing NCP125x family and is now specified at 10 mA

(max) along the whole temperature range. Assume you want

a start−up time less than 1.5 s at the lowest input voltage,

85 V rms. The V

cc

capacitor is 10 mF and the controller

turn−on voltage is 20 V (max). How much current do you

need from a 120 V bulk voltage? For the capacitor you must

deliver

I

2

u

DV @ C

Vcc

t

+

20 10u

1.5

[ 133 mA

(eq. 1)

To this value, you must add the IC own consumption of

10 mA, pushing I

2

to 145 mA with some margin. To deliver

these 145 mA from the bulk rail, resistance R

1

must be of the

following value

R

1

t

120*20

145u

+ 690 kW

(eq. 2)

Considering a normalized 680 kW resistance, a high−line

dc level on the bulk capacitor of 375 V and a 14 V operating

V

cc

, then the power permanently dissipated is

P

d

+

(375*14)

2

680k

[ 191 mW

(eq. 3)

This value may be considered low depending on the

performance you want to achieve. If you try to beat the

300 mW limit, you may have a chance to meet this number

providing the converter’s consumption is reduced at no load.

If you now want to be way less than this value, there are

several options:

1. Trade a slightly larger start−up time: by increasing

the start−up time to 3 s, the charging current drops

to 75 mA, the resistance becomes 1.3 MW and the

dissipated power drops to 100 mW.

2. Decrease the V

cc

capacitor to 4.7 mF. For instance,

increasing a little the auxiliary winding turns ratio

may improve the auxiliary V

cc

take−over time and

a 4.7 mF capacitor is enough to start up in all

conditions. In this case, you approach values

obtained with those obtained in point 1.

Besides excessive power dissipation, another drawback of

this solution is the maintaining of V

cc

a long time while the

converter has been unplugged from the mains outlet. If the

IC is latched and the user wants a quick reset, this solution

lengthens the reset time quite significantly as V

cc

does not

immediately drop to its reset value.

A second possibility is to connect the start−up resistance

to the input line directly. One of the bridge diode will ensure

half−wave rectification and the rms voltage value across the

resistance will be significantly reduced to the benefit of the

dissipated power. Figure 2 represents this solution widely

implemented in ac−dc adapters.

www.onsemi.com

APPLICATION NOTE