下载

© Freescale Semiconductor, Inc., 2005. All rights reserved.

AN1082

Rev 4, 05/2005

Freescale Semiconductor

Application Note

Simple Design for a 4-20 mA Transmitter

Interface Using a Pressure Sensor

by: Jean Claude Hamelain

Toulouse Application Lab Manager

INTRODUCTION

Pressure is a very important parameter in most industrial

applications such as air conditioning, liquid level sensing and

flow control.

In most cases, the sensor is located close to the measured

source in a very noisy environment, far away from the receiver

(recorder, computer, automatic controller, etc.)

The transmission line can be as long as a few hundred

meters and is subject to electromagnetic noise when the

signal is transmitted as voltage. If the signal is transmitted as

a current it is easier to recover at the receiving end and is less

affected by the length of the transmission line.

The purpose of this note is to describe a simple circuit

which can achieve high performance, using standard pressure

sensors, operational amplifiers and discrete devices.

PERFORMANCES

The following performances have been achieved using an

MPXV2102DP pressure sensor and an MC33079 quad

operational amplifier. The MPXV2102DP is a 100 kPa

temperature compensated differential pressure sensor. The

load is a 150 ohm resistor at the end of a 50 meter telephone

line. The 15 volt power supply is connected at the receiver

end.

Basic Circuit

The MPXV2102DP pressure sensor is a very high

performance piezoresistive pressure sensor. Manufacturing

technologies include standard bipolar processing techniques

with state of the art metallization and on-chip laser trim for

offset and temperature compensation.

This unique design, coupled with computer laser trimming,

gives this device excellent performance at competitive cost for

demanding applications such as automotive, industrial or

healthcare.

MC33078, 79 operational amplifiers are specially designed

for very low input voltage, a high output voltage swing and

very good stability versus temperature changes.

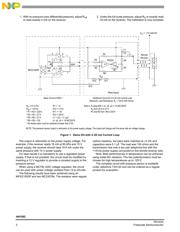

First Stage

The MPXV2102 and the operational amplifier are directly

powered by the 15 Vdc source. The first stage is a simple true

differential amplifier made with both of the operational

amplifiers in the MC33078. The potentiometer, R

G

, provides

adjustment for the output.

Current Generator

The voltage to current conversion is made with a unity gain

differential amplifier, one of the four operational amplifiers in

an MC33079. The two output connections from the first stage

are connected to the input of this amplifier through R3 and R5.

Good linearity is achieved by the matching between R3, R4,

R5 and R6, providing a good common mode rejection. For the

same reason, a good match between resistors R8 and R9 is

needed.

The MC33078 or MC33079 has a limited current output;

therefore, a 2N2222 general purpose transistor is connected

as the actual output current source to provide a 20 mA output.

To achieve good performance with a very long transmission

line it may be necessary to place some capacitors (C1, C2)

between the power supply and output to prevent oscillations.

Calibration

The circuit is electrically connected to the 15 Vdc power

supply and to the load resistor (receiver).

The high pressure is connected to the pressure port and the

low pressure (if using a differential pressure sensor), is

connected to the vacuum port.

It is important to perform the calibration with the actual

transmission line connected.

The circuit needs only two adjustments to achieve the 4-

20mA output current.

Power Supply +15 Vdc, 30 mA

Connecting Line 3 wire telephone cable

Load Resistance 150 to 400 Ohms

Temperature Range -40 to +85°C (up to +125°C with special

hardware)

Pressure Range 0 to 100 kPa

Total Maximum Error Better than 2% full scale