下载

ã

1998 Microchip Technology Inc. DS00686A-page 1

M

AN686

SCOPE

This application note discusses what microcontroller

supervisory devices are, why they are needed and

some factors to consider when choosing one. Supervi-

sory devices is a broad term that encompasses POR

(power on reset) devices, BOD (brown-out detect)

devices and watchdog timer devices. This application

note will cover supervisor devices with POR and BOD

functions only.

WHAT DOES A SUPERVISORY

CIRCUIT DO?

A supervisory circuit can be used for several different

applications, but there are two primary functions that a

supervisor provides:

1. During a power up sequence, the device holds a

microcontroller in reset until the system power

has come up to the correct level and stabilized

(the POR function), and

2. reset the controller immediately if the power

drops below a nominal value either at power

down or during a ‘brown-out’ condition.

Some supervisor devices also provide things like low

battery warning, watchdog timer and other more elab-

orate functions that are beyond the scope of this appli-

cation note.

WHY DO I NEED A SUPERVISORY

CIRCUIT ANYWAY?

One question system designers may ask themselves

is, “Why do I need one of these things anyway?” There

are 3 situations that you must consider when answer-

ing this question:

3. What would happen to the microcontroller (or

other devices in the system) if there was noise

on the supply voltage as it powers up?

4. What would happen if there is a glitch on the

power supply while the system is running?

5. What does the microcontroller do when the sys-

tem power is turned off?

If you ponder these questions and have visions of

phone calls from angry customers, then you might con-

sider using a supervisor device.

In the Beginning: Power-Up Problems

Most designers working on a prototype system are

familiar with putting a reset switch of some kind on the

reset pin of the microcontroller. Why? Because they are

making both hardware and firmware changes, which-

sometimes cause the system to malfunction, resulting

in the microcontroller no longer behaving in a rational

manner. Sometimes it just plain doesn’t work. The sys-

tem designer pushes the reset button a couple of times

to determine if the problem goes away. If not, more

changes are made and the process continues. The

push button provides a means of manually resetting the

system. This may work fine for the system development

phase, but what do you do to ensure proper system

power-up when it goes into production?

Many systems rely on a simple pullup resistor tied to

the reset line and their system works fine every time.

But what if different components in the system are all

powering up as the supply voltage is ramping up and

noise is injected onto the supply line? Most microcon-

trollers have specs that describe power up ramps for

proper initialization of the controller. A glitch on the sup-

ply line may very well cause the microcontroller (or

some other component) to power-up incorrectly and

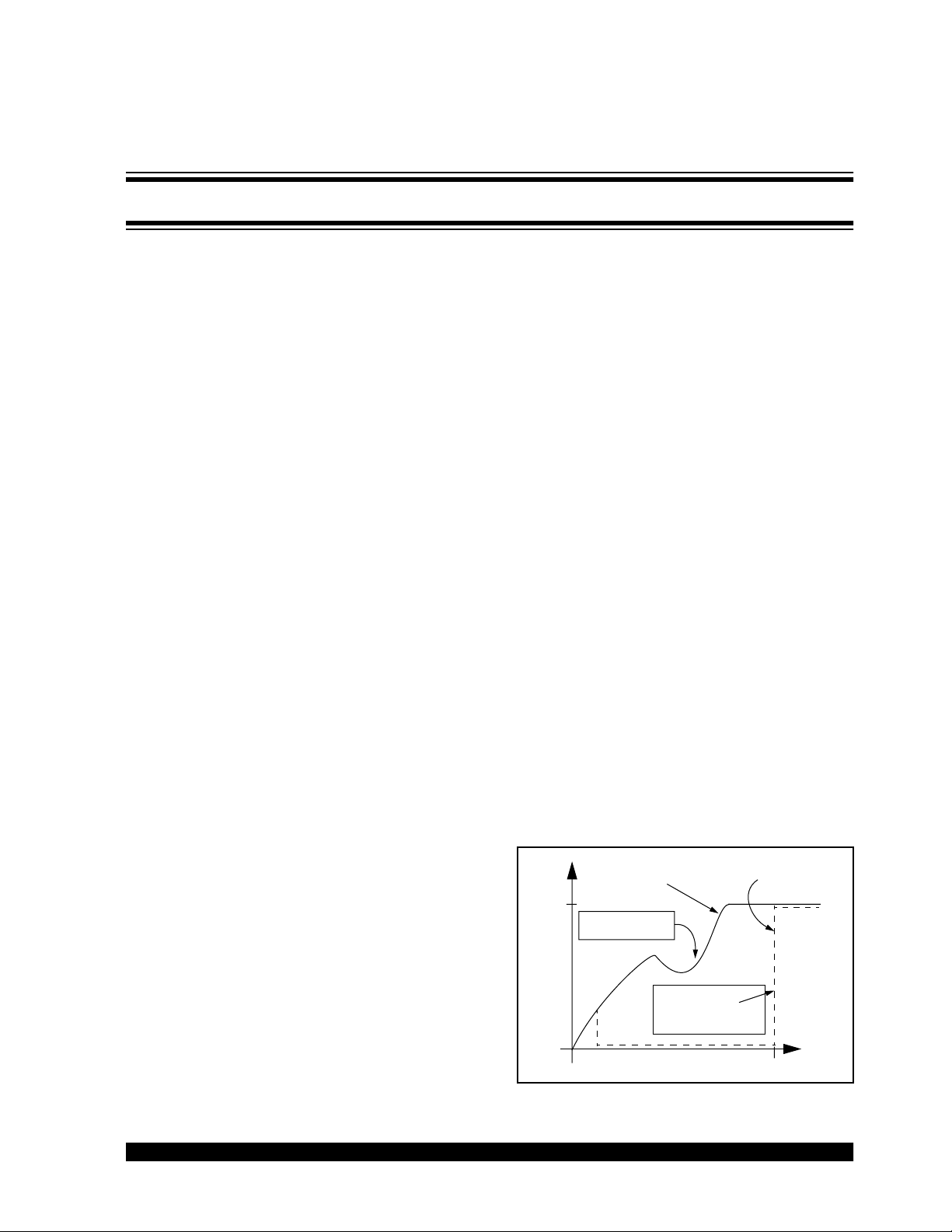

prevent the system from operating as intended. See

Figure 1. A supervisor device solves this problem by

holding the microcontroller in reset until the power has

reached a stable level. Timeout periods vary for differ-

ent devices but typical values are 150ms - 500ms.

When the timeout period is complete, the device will

release the reset line and allow the microcontroller to

begin exection of its code.

FIGURE 1: POR FUNCTION

0

Time

Voltage

0

500ms

5V

Supervisor holds

microcontroller in

reset until the supply

voltage is stable

Possible glitch in

power supply ramp

Supervisor

Output

Pin

Supply

Voltage

Understanding and Using Supervisory Circuits