下载

Keywords:

Internet of Things, IoT, Industrial Internet of Things, IIoT, microPLC, IO-Link

APPLICATION NOTE 6142

INDUSTRIAL INTERNET OF THINGS (IIOT) AND ITS IMPACT ON THE DESIGN OF

AUTOMATION SYSTEMS

By:

Suhel Dhanani, Sr. Principal MTS, Control and Automation Strategic Marketing, Maxim Integrated

Abstract:

This application note examines the system architecture for an Industrial Internet of Things (IIoT). It focuses on the design challenges that must be solved to successfully

implement IIoT-capable systems. Special attention is given to the growing need for more and smarter sensors, microPLCs, and the emerging IO-Link standard.

The Internet of Things, or the IoT, is a current buzzword gaining traction in a number of industries. A variation, the

Industrial

IoT (IIoT), is quite the rage within

automation companies seeking to add a high-margin software component to

their traditional businesses. Coming from a semiconductor chip company whose devices enable much of the automation

equipment out there, we at Maxim Integrated have a unique perspective on how automation system architectures are

evolving to support the IIoT.

This application note looks at the system architecture for the IIoT, and focuses on the design challenges that must be

solved to successfully implement IIoT-capable systems. Special attention is given to the growing need for more and

smarter sensors, MicroPLCs, and the emerging IO-Link

standard.

The Path to Industry 4.0 Is via the IIoT

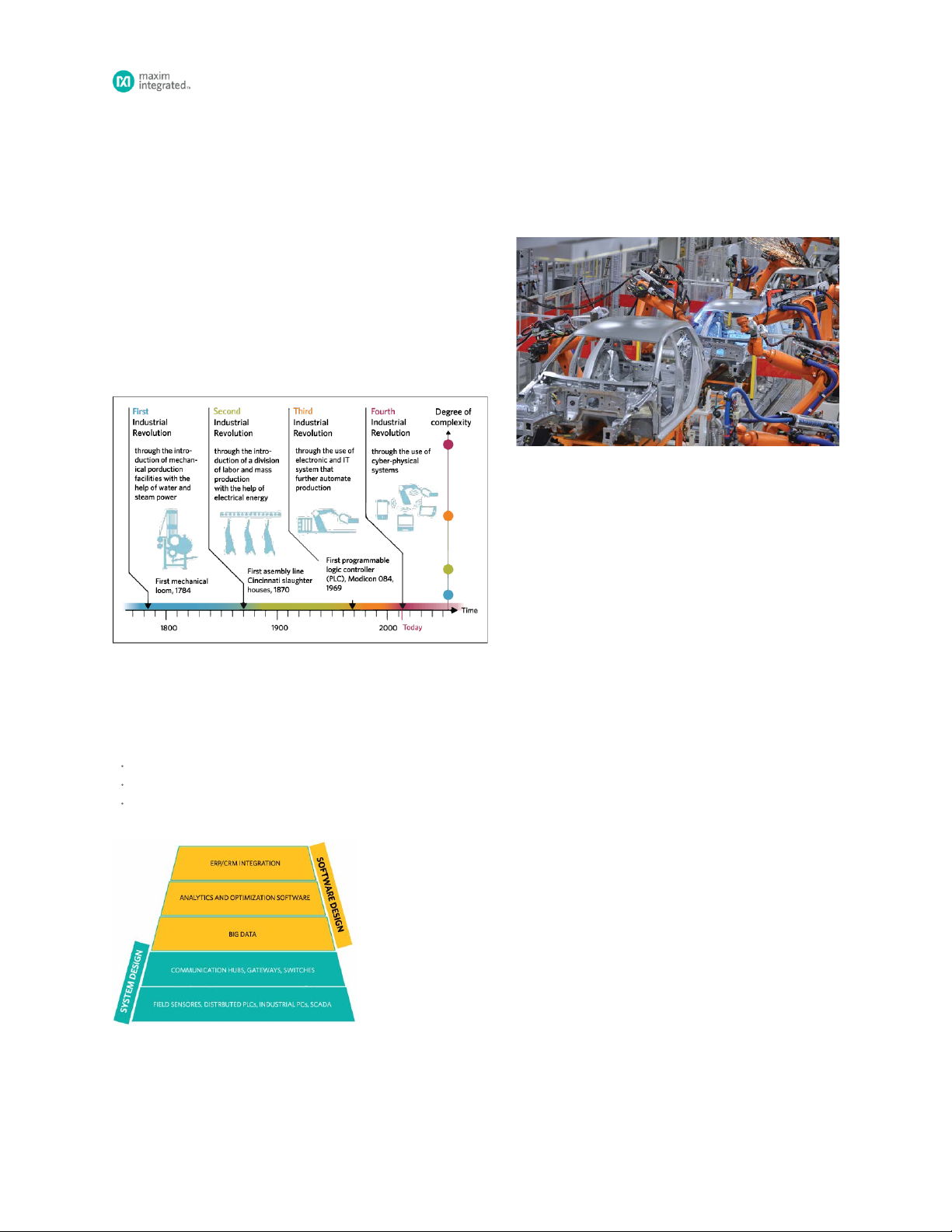

Siemens categorizes the industrial revolutions in three distinct phases. The first industrial revolution started with the

introduction of mechanical production facilities helped by water and steam power. The second revolution began with the

introduction of electric power. The third came with the advent of automation, which could be argued happened when the

first programmable logic controllers (PLCs) appeared on factory floors. Now Siemens, along with the German government,

believe that it is time for Industry 4.0, a new revolution when custom components will be produced in a fully automated

fashion (

Figure 1).

Figure 1. The path to Industry 4.0 is via the IIoT. Graphic source is: DFKI (2011).

In Industry 4.0 production from inception to delivery

is based on communication among the parts to be created and the assembly line machines. Germany is pushing this IIoT movement

to leverage their manufacturing and embedded software expertise within the industrial domain. In the United States General Electric (GE) is working on a similar initiative called, "The

Industrial Internet."

Manufacturing is the sector that can get the most leverage from the IoT because of the sheer amount of data captured and processed within manufacturing. And, data is the underpinning

of the IIoT since it can all be analyzed and visualized to help optimize operations and costs. Within manufacturing, the intelligent sensors, distributed control, and complex, secure

software are the glue for this new revolution.

What Exactly Is the IIoT?

Industry experts and market analysts define the IIoT.

"The Industrial Internet of Things (IIoT) is the next wave of innovation impacting the way the world connects and optimizes machines. The IIoT, through the use of sensors,

advanced analytics and intelligent decision making, will profoundly transform the way field assets connect and communicate with the enterprise."

"Leading O&G companies are building an infrastructure where sensors, data management, advanced analytics and automation are being used to unlock production, reduce operating

costs and optimize assets."

"The Industrial Internet, a connected network of intelligent machines working the way they are intended, will transform business as dramatically as the consumer Internet has

changed our lives."

Another way to define the IIoT is to look at industrial network in the form of layers shown in

Figure 2.

Figure 2. The automation systems stack that enables IIoT.

®

®

1

2

3

4

Page 1 of 6