下载

Mechanical Design Notes

www.vishay.com

Vishay Semiconductors

Rev. 1.6, 18-Feb-13

1

Document Number: 80075

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

Mechanical Design Notes

There are many aspects in the design of an appliance, which

will affect the IR sensitivity of the receiver such as window

size, window material, distance of the receiver to the

window or to a light guide.

WINDOW

The size of the window in front of the IR receiver should be

large enough so that the viewing angle of the IR receiver is

not overly restricted. The window size and the distance of

the IR receiver behind the window should be designed to

enable a directivity of at least ± 50°. A module with a

mechanical holder (e.g. TSOP4838AY1) can sometimes help

to place the sensitive area of the IR receiver module closer

to the window.

When the front panel of an appliance is black, it is usually

desired that the optical window in front of the IR receiver

also be tinted black. That means that a plastic material is

required, which is transparent for infrared signals but

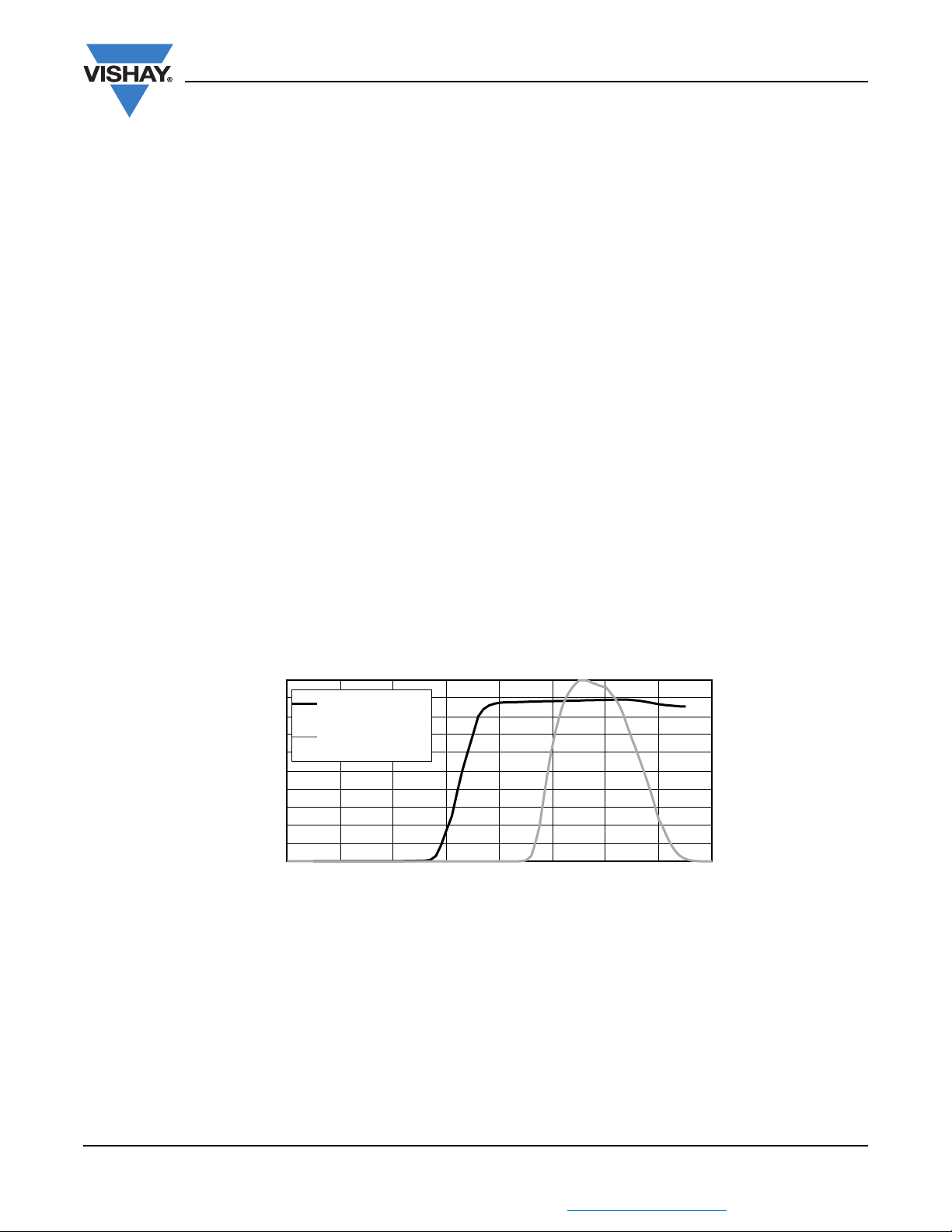

opaque for visible light. The diagram in figure 1 shows an

example of the spectral transmittance of such a plastic

material (Bayer Makrolon color 45/601).

The cut-off wavelength of the window material should be

between 700 nm and 850 nm in order to appear black and

in order not to absorb IR signal energy.

There is a loss of power in every front panel of about 8 %

due to reflection (4 % at each side). There is a compromise

necessary on the design of the panel thickness. On the one

hand, the thickness of the panel should be kept small to

minimize the loss of energy in the plastic material. On the

other hand, the thickness of the plastic should not be too

small (or the color of the plastic too light) in order to avoid

being able to see inside the appliance. In contrast to other

products that have a shiny external metal shielding, the

Vishay TSOP IR receiver modules have a black package

with internal shielding, which prevents visibility behind the

front panel.

The relationship between the necessary thickness and the

optical transmittance is given by:

()= (1 - ) x e

(-a() x d)

() = Spectral transmittance

=

Constant factor for reflection loss (typically about

0.08

)

e = 2.718282

() = Coefficient of plastic material (about 0.03 mm

-1

at

950 nm in the example above)

d = Thickness of front panel

There are several plastic materials with such a spectral

behavior. Some examples of polycarbonate are:

• Makrolon 2805; color #: 45-601 (blue - black);

supplier: Bayer

• Makrolon 2805: color #: 45-401 (green - black);

supplier: Bayer

Fig. 1 - Spectral Transmittance for IR Transmissive Window Material

Another very common design is a silver colored front panel,

usually either equipped with tiny holes for the IR signal to

pass through or a partially reflecting material for this

purpose. Although stylish, this design is very non-optimal in

terms of transmission range as there is a high loss of signal

through the panel.

0

10

20

30

40

50

60

70

80

90

100

400 500 600 700 800 900 1000 1100 1200

Wavelength (nm)

Spectral transmittance (%)

spectral transmittance

of tinted filter

spectral sensitivity of

TSOP IR receiver