下载

2/15/16

APPLICATION NOTES for SMD LEDs

1

Page

STORAGE CONDITIONS

SMD devices are usually moisture/reow sensitive. Moisture from atmospheric humidity enters permeable

packaging materials by diffusion. Assembly processed used to solder SMD packages to PCBs expose the entire

package body to temperature between 160° - 260°. During solder reow, rapid moisture expansion can result in

package cracking, delamination of critical interfaces within the package, or damaged gold wire.

1. Scope: Application notes listed in this document apply to SMD products include the AA, AP, AM, APK, and

AT series.

2. Unopened moisture barrier bag (MBB) shall be stored at temperature below 40° with humidity below

90%RH.

3. After the MBB has been opened, the LEDs should be used according to the oor life specied in the table

below.

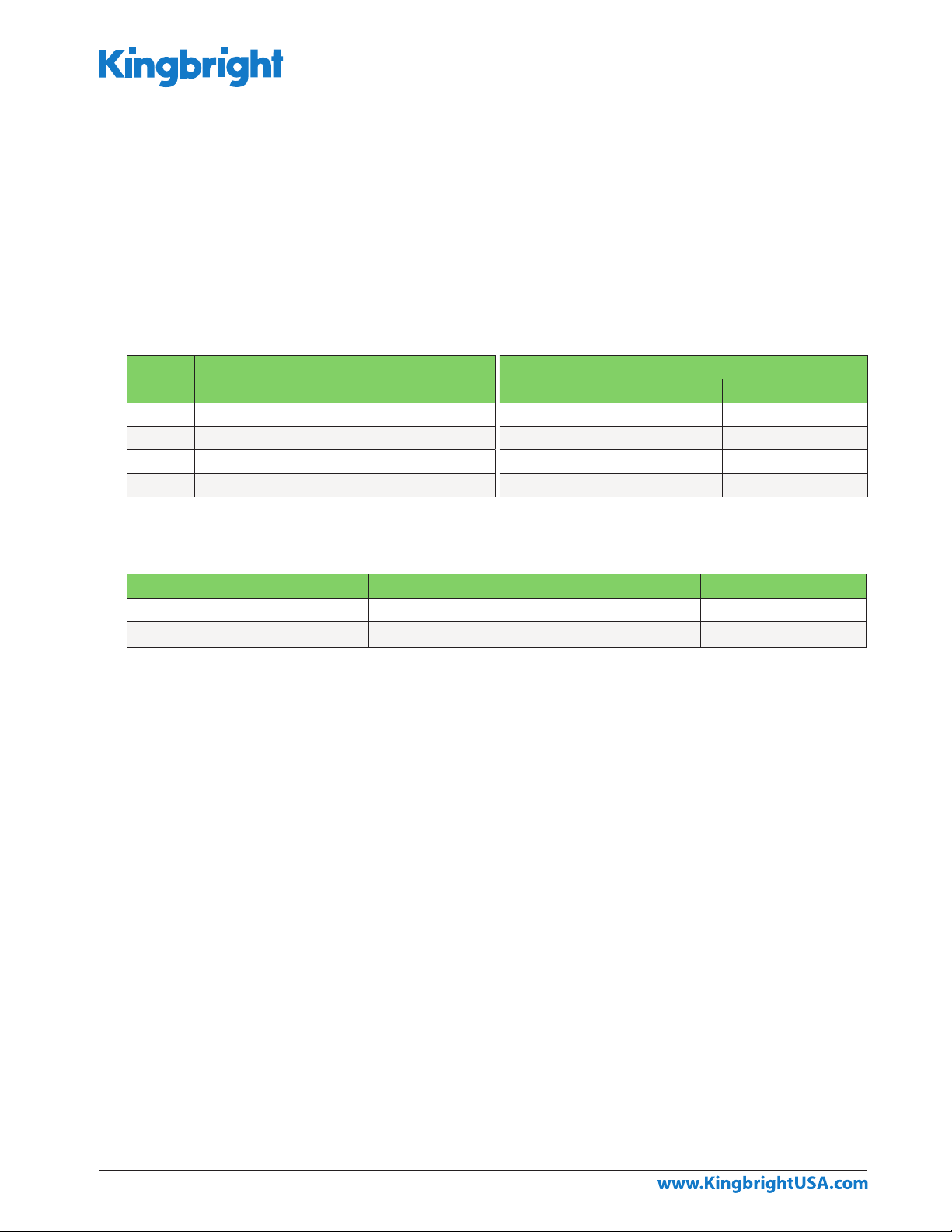

LEVEL

FLOOR LIFE

LEVEL

FLOOR LIFE

TIME CONDITIONS TIME CONDITIONS

1 Unlimited ≤ 30°C / 85% RH 4 72 hours ≤ 30°C / 60% RH

2 1 year ≤ 30°C / 60% RH 5 48 hours ≤ 30°C / 60% RH

2a 4 weeks ≤ 30°C / 60% RH 5a 24 hours ≤ 30°C / 60% RH

3 168 hours ≤ 30°C / 60% RH 6 Time on Label (TOL) ≤ 30°C / 60% RH

4. If the Humidity Indicator Card (HIC)’s 10% mark has changed, or the LEDs have not been used within the

oor life specied, they should be baked with the following conditions to reset the oor life:

TYPE TEMPERATURE HUMIDITY BAKE TIME

When still in carrier tape 60 ± 3°C < 5%RH 100H

When out of carrier tape 110°C / 10H

Note : No more than once

5. Do not store LEDs in an environment where high humidity or acidic/basic chemicals are present, as they will

degrade the LED’s metallic surfaces.

6. LED leadframe and soldering pads (cathode and anode) are plated with gold, tin, or other metals. Under

long-term exposure to open air, the exposed pins and pads may become oxidized causing poor

solderability. Therefore opened but unused parts must be stored in sealed containers. Suggest to store

unused parts in the original moisture barrier bag.

7. Moisture control for components already mounted on PCB: If the PCB will not undergo additional reow

soldering or high-temperature processes, then no special treatment is required for the mounted

moisture-sensitive SMD components. If the PCB will undergo multiple reow soldering or other

high-temperature processes, including rework, then the SMD component’s cumulative exposure time until

the nal high-temperature process must be controlled to within the specied time limit.

SOLDERING

1. Do not apply stress to the leads when the component is heated above 85°C, otherwise internal wire bonds

may be damaged.

2. SMD products must be mounted according to specied soldering pad patterns. Refer to the product

datasheet for details. Solder paste must be evenly applied to each soldering pad to insure proper bonding

and positioning of the component.

3. After soldering, allow at least three minutes for the component to cool to room temperature before further

operations.